Our Services

Prototypes and Development Projects

TCT has experience in multiple composite part development projects and has the ability to design and manufacture molds and produce working prototypes all in-house. Fast turnaround and flexibility in redesign is a key operational aspect of TCT.

TCT's flexible mold tooling is an ideal fit for low cost prototype and development of working structural parts for testing.

Current Projects and Developments:

- Major OEM Spring project including multiple variations of prototypes.

- Tier One Supplier multi prototypes and development project for spring suspension and working prototypes in car.

- Major overseas OEM spring development project with multiple prototypes.

- After-market sway bar manufacturer development and working prototypes.

- Military torsion bar development with prototype test parts.

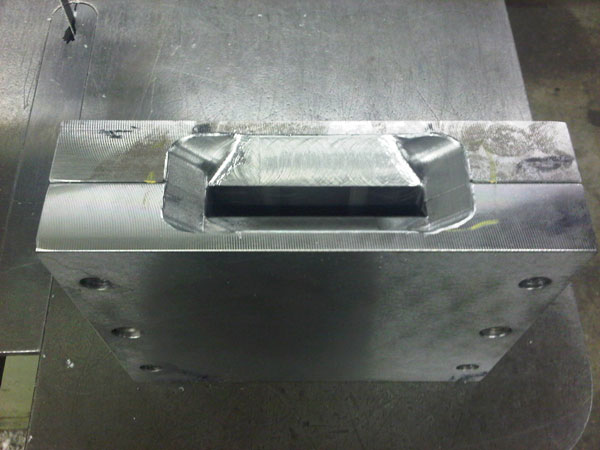

Mold and Tooling

TCT is vertically integrated with the ability to design, machine, and build molds, dies, filament winding mandrels, and infusion systems for composite part manufacturing.

Having all the necessary CNC machining equipment in-house allows for fast turnarounds.

Fast reaction to engineering changes to mold designs or re-machining of tooling. This is the rare advantage of having the capability to manufacturer composite parts and the tooling to build the parts all under one organization.

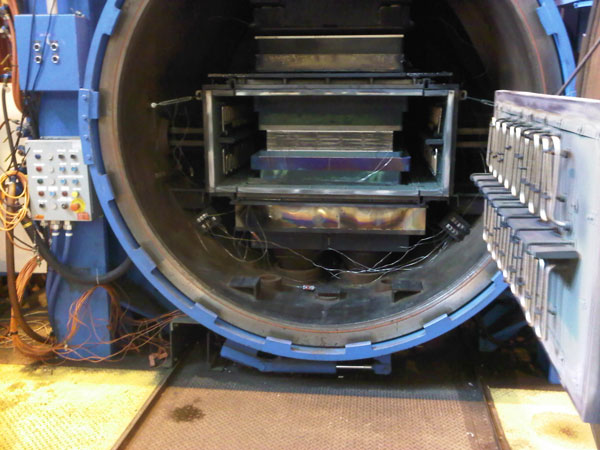

Part Manufacturing

Long and short run production capabilities utilizing the following techniques:

- Hybrid Selective Ply Pultrusion System

- 4 Axis Filament winding machine

- 4 Post double acting 19 ton Composite Molding Press

- RTM Resin Transfer Molding

- Vacuum Infusion Molding

- Open Molding

Automotive Industries

Composite Capabilities:

- Uniform thickness composite leaf springs continuous fibers.

- Variable thickness composite leaf springs of continuous fibers.

- Composite Sway Bars, solid core and hollow core

- Composite Torsion Bars, solid core and hollow core

- Carbon Fiber Drive Shafts, custom made tubular.

- Composite Coil Springs

- Composite Engine Strut Brace

- Composite Control Arms

- Composite Axles

Aerospace Industries

Composite Aerospace Product Capabilities

- Composite light-weight foam cored seat back table trays

- Carbon fiber food and beverage carts for weight savings

- Various interior design components replacement of non structual plastic components with cost effective light-weight composites

- Fire resistant high strength light-weight aerospace pallets and shipping containers

Military Industries

Composite Military Product Capabilities

- Composite light-weight torsion bars

- Composite light-weight leaf springs

- Composite light-weight coil springs

- Composite covers

- Ballistic paneling **

- Blast paneling

- Composite tow bars

**Provided in partnership

TCT has the ability to custom manufacture for short and long run production of the above components. For any products that are not listed, please send an inquiry to the contacts on this page.

Contact Us